There is a lot of buzz these days about there being a shortage of supply chain and logistics talent in the market. While much of the focus has been on white-collar positions, finding, hiring, and retaining talent at the frontlines of operations – such as drivers and distribution center employees – is equally challenging and important. And this holds true not only for companies that manage logistics operations in-house, but for logistics service providers as well.

Why must manufacturers, retailers, distributors, and logistics service providers think more strategically about talent management? Because best-in-class execution depends on best-in-class people.

I speak from personal experience. When I started my career at Motorola in the early 90s, I worked in a group called People Reaching Out for Innovation in Semiconductor Manufacturing, or PRISM for short. Our mission was to develop technologies and business processes that would enable us to transfer semiconductor packaging from Asia to the United States in order to shorten our supply chain, decrease lead times, and respond more quickly to customer demands and issues. To overcome Asia’s labor cost advantage, we invested heavily in state-of-the-art automation equipment and IT systems, and we streamlined and integrated work processes to maximize productivity and throughput. PRISM started out as a pilot production line (9 am to 5 pm, Monday through Friday), but we were so successful, the company quickly decided to scale us into a high-volume operation (24 hours a day, 7 days a week, 365 days a year).

In the early days of the ramp-up process, as we struggled to find people to work the night shifts, I volunteered to be a second shift supervisor. I’ll spare you all the details, but after several weeks of dealing with a wide variety of production issues and getting paged in the middle of the night countless times, I learned a couple of things:

It doesn’t matter how much you invest in technology or processes – if you don’t also invest in people, you won’t succeed.

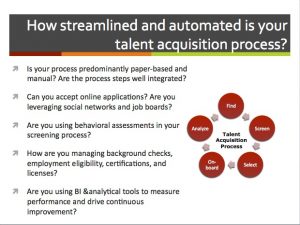

If you don’t have a well-defined strategy and execution plan upfront around finding, screening, hiring, and onboarding talent, you will pay for it later in lost productivity, quality and safety issues, and high turnover rates.

I shared this story a couple of weeks ago in a webcast titled Making the Case for Competing on Logistics Talent, where I co-presented with Tom Cantor, PHR Strategic Products Consultant at Kronos. I encourage you to watch the webcast to get more details and insights on this important and timely topic. As a teaser, here is a slide from my presentation that raises some questions you should ask regarding your talent acquisition process.

Here’s the bottom line: Innovation — another popular buzz term these days — doesn’t just apply to technology and processes; you also have to innovate the people side of your supply chain, which includes streamlining and automating your talent acquisition process in order to find the right people, with the right skills, in the right places, at the right time — before your competition does!

Leave a Reply